HOME >technical information

Technical information

MLA

technology

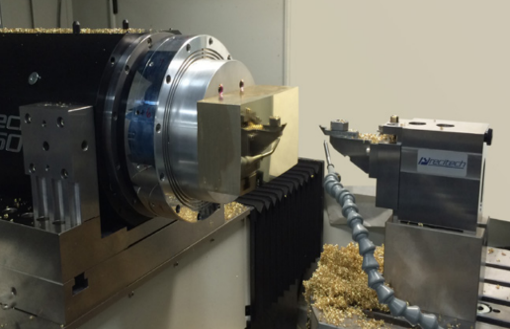

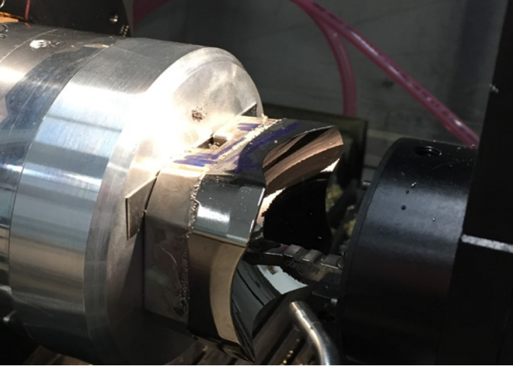

Freeform processing technology

Freeform optics are not symmetric about the optical axis. This characteristic offers several attractive features to optical designers, such as correcting multiple aberrations with fewer optical surfaces and making systems more compact and lightweight.

Freeform optics provide significant advantages in system integration and find broad applications across various fields including illumination, aerospace, biomedical engineering, green energy, optical imaging, and automotive industries.

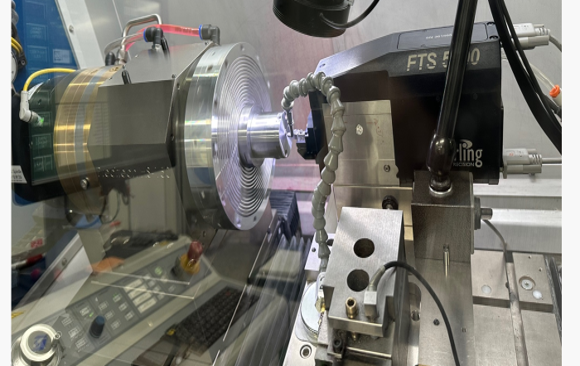

MLA (Microlens Array) fabrication technology stands out as an advanced technique for manufacturing arrays of miniature lenses. Microlens arrays consist of small-sized lenses arranged in a structured pattern, finding applications across various fields.

This technology is primarily employed in aerospace and defense, materials processing, medical and biophotonics, and industrial production systems for creating or adjusting arrays of lenses.

Microlens arrays are utilized to achieve precise control over light distribution, enhance optical performance, and enable novel functionalities in optical systems. They play a crucial role in improving imaging systems, optical communications, laser processing, and other optical applications requiring micro-scale optics. The fabrication techniques for MLA involve advanced manufacturing processes such as photolithography, etching, or molding, ensuring high precision and reproducibility of microlens array structures tailored to specific application requirements.